Teams from Lyndon SGB and Brandsafway’s in-house design and engineering teams have designed two highly intricate and complex designs for Manchester Town Hall’s temporary roofing, being erected by Lyndon SGB #OurTownHall scaffolding teams for Lendlease now.

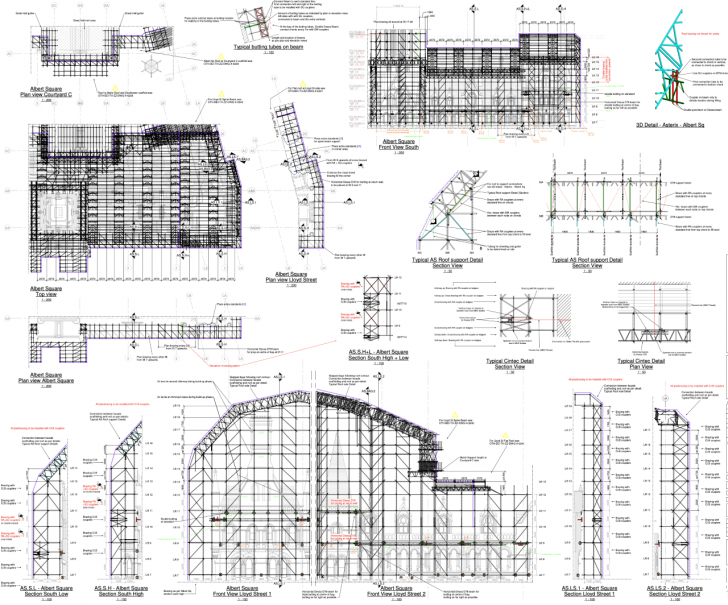

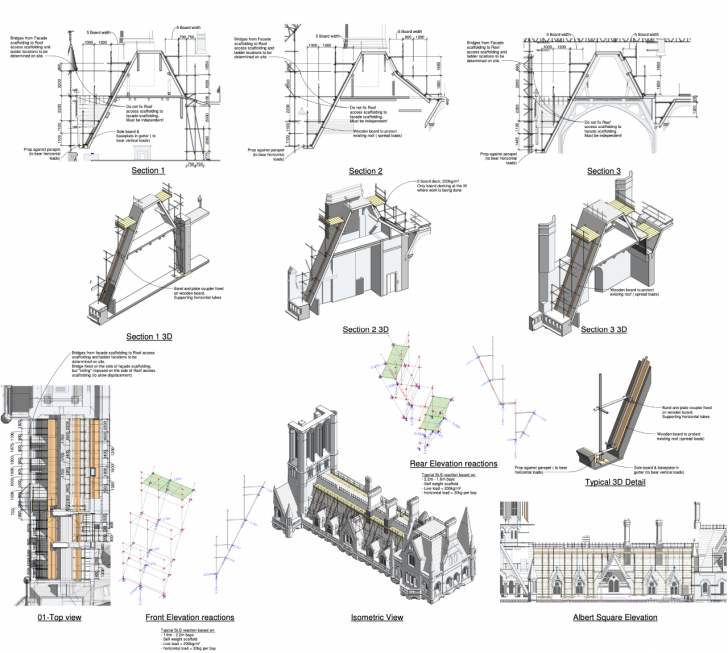

The photograph in this article shows two structures – a vast 1200m² temporary roof at Albert Square South and large-scale access scaffold below. The temporary roofs are supported on a 34m high scaffold with the top freestanding up to 15m above the last tie level in some locations. The highly complex scaffold structures were designed using Revit drawing software and the SCIA analysis software, with Regional Design Manager David Flaherty, overseeing the designs on the project.

The temporary roof structure elements were designed by the our global partners, Brandsafway with their design team in Holland (Maarten Van Dyke and Bram Sanders) working up the right solution for the main contractor, Lendlease to approve. And the roof access scaffold below was drawn using Revit, mostly by Jamey Campbell in Glasgow under the guidance of Maarten Van Dyke, who did the remainder of the drawing work plus all the calculations.

The Lyndon SGB temporary roofing solution was erected using Asterix beams, by Craig Parry, Nathan Smith and Shane Scoynes and teams from our Manchester branch, under Regional Manager, Jon Cooke’s management.

Where the Albert Square South Roof butts onto the Lloyd Street roof, the structure is supported by a 15m span spine beam spanning between Lloyd Street and Courtyard C. As a result of the high tie loads due to the 15m height of scaffold free standing above the last tie level, the top tie level had to be fixed through the facade of the building into the cross walls and floor slabs using Cyntec ties (on the Lloyd Street gable elevation of Albert Square’s south roof).

The frames were craned into position two bays at a time. The remaining bays in the gaps between the ones already in position were erected in-situ. And once all frames were installed, the Layher Keder XL roof sheeting was pulled across on the Keder XL tracks fixed to the top of each roof truss – providing perfect, safe weather protection.

Speaking about the design process, Lyndon SGB Design Manager, Chris Jones said: “The Revit drawings were fantastic for this phase of the project as the client was able to see a 3D model of each temporary roof drawn around the 3D model of the building and all potential clashes were designed out.

“Each of the Revit drawings has a QR code which enabled the client to view the 3D model of the temporary roofs, zoom in and out and spin it around to see particular areas of interest to them. It worked out really well.”